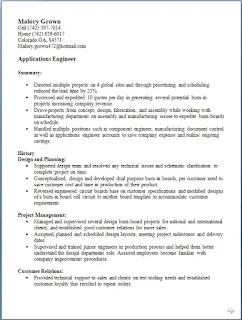

- Directed multiple projects on 4 global sites and through prioritizing and scheduling reduced the lead time by 25%

- Processed and expedited 10 quotes per day in generating several potential burn-in projects increasing company revenue.

- Drove projects from concept, design, fabrication, and assembly while working with manufacturing department on assembly and manufacturing issues to expedite burn-boards on schedule.

- Handled multiple positions such as component engineer, manufacturing document control as well as applications engineer accounts to save company expense and realize ongoing savings.

- Supported design team and resolved any technical issues and schematic clarification to complete project on time.

- Conceptualized, design and developed dual purpose burn-in boards, per customer need to save customer cost and time in production of their product.

- Reversed engineered circuit boards base on customer specifications and modified designs of a burn-in board cell circuit to another board template to accommodate customer requirement.

- Managed and supervised several design burn-board projects for national and international clients, and established good customer relations for more sales.

- Assigned, planned and scheduled design layouts, meeting project milestones and delivery dates.

- Supervised and trained junior engineers in production process and helped them better understand the design department role. Assisted employees become familiar with company improvement procedures.

- Provided technical support to sales and clients on test tooling needs and established customer loyalty that resulted to repeat orders.

- Coordinated and negotiated with various vendors and obtained best price and delivery for components and sockets to be used in projects to save cost in production and increase company revenue.

- Established rapport and credibility both in internal and external customers by providing excellent service.

Download Resume Format

0 comments:

Post a Comment