Download Resume Format

Machining Manager Sample Resume Format in Word Free Download

Sample Template Example of Beautiful Excellent Professional Curriculum Vitae / Resume / CV Format with Career Objective, Job Description, Skills & Work Experience for Freshers & Experienced in Word / Doc / Pdf Free Download

Download Resume Format

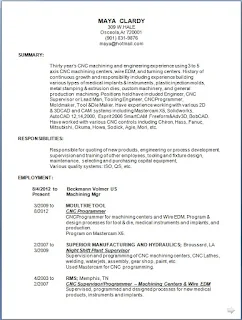

MAYA CLARDY

309 W.HALE

Osceola,Ar 720001

(901) 831-9876

maya@hotmail.com

SUMMARY:

Thirty year’s CNC

machining and engineering experience using 3 to 5 axis

CNC machining centers, wire EDM, and turning centers. History of continuous growth and responsibility

including experience building various types of medical implants

& instruments, plastic injection molds, metal stamping & extrusion dies,

custom machinery, and general production machining. Positions held have included

Engineer, CNC Supervisor or Lead Man, Tooling Engineer,

CNCProgrammer, Moldmaker,

Tool &Die Maker. Have experience working with various 2D & 3DCAD and CAM systems

including Mastercam X5, Solidworks, AutoCAD

12,14,2000, Esprit 2006 SmartCAM Freeform&Adv3D, BobCAD. Have worked

with various CNC controls including Chiron, Hass, Fanuc,

Mitsubishi,

Okuma, Howa, Sodick, Agie, Mori, etc.

RESPONSIBILITIES:

Responsible for

quoting of new products, engineering or process development, supervision

and training of other employees, tooling and fixture design, maintenance, selecting and purchasing capital equipment,

Various

quality systems: ISO, QS, etc.

EMPLOYMENT:

8/4/2012 to Beckmann Volmer US

3/2009

to MOULTRIE TOOL

8/2012 CNC

Programmer

CNCProgrammer

for machining centers and Wire EDM. Program & design

processes for tool & die, medical instruments and implants, and production.

Program

on Mastercam X5.

2/2007

to SUPERIOR MANUFACTURING AND HYDRAULICS; Broussard, LA

3/2009 Night Shift Plant Supervisor

Supervision

and programming of CNC machining centers, CNC Lathes, welding,

waterjets, assembly, gear shop, paint, etc.

Used

Mastercam for CNC programming.

4/2003

to RMS; Memphis, TN

2/2007 CNC Supervisor/Programmer –

Machining Centers & Wire EDM

Supervised,

programmed and designed processes for new medical products,

instruments and implants.

Programmed

on Mastercam X2, Espirt 4 & 5 axis mills

Used

and programmed Micro Vu Vision and CMM

4/2000

to ELKTON DIE CASTING; Elkton, KY

4/2003 CNC Supervisor

Start-up,

supervision and programming of Machining Dept.

Used

Mastercam for CNC programming.

9/1995

to PIPER IMPACT; New Albany, MS

4/2000 Machining Engineer

Start-up

and support of Chiron CNC Machining Center Department.

New

Product development including quoting, planning, new equipment acquisition, fixture & cutting

tool design, CNC programming, set-up & operator

training.

Supported

production as necessary to machine products for the automotive industry as well as the military. Experienced

in QS9000, PPAP,

FMEA, APQP, etc.

9/1993 to HMC TECHNOLOGIES;

New Albany, MS

9/1995 Supervisor/Programmer – CNC Wire EDM

& CNC Milling Dept.

Supervised

the CNC Dept. Responsible for quoting and tool design in the building of various custom tooling,

machinery, and general production machining.

3/1992 to TUPELO TOOL & DIE

INC.; Tupelo, MS

9/1993 Supervisor/Programmer – CNC Wire EDM

& Machining Center

Used

SmartCAM for CNC programming.

1/1990 to ARMIN TOOL; South

Elgin, IL

3/1992 Programmer/Set-up

Programmed

and set-up multi-pallet MAZAK machining centers to manufacture

custom plastic injection molds.

6/1984 to HARRY L. BRAUN CO.;

Crystal Lake, IL

1/1990 Programmer/Set-up

Programmed

and set-up MAKINO CNC machining center to build custom plastic

injection molds.

EDUCATION:

2 years ELGIN COMMUNITY

COLLEGE; Elgin, IL

Computer

Aided Drafting and Manufacturing

AutoCAD 2000

Mastercam X3 Adv 3D Milling & 5 Axis

H.D. JACOB’S HIGH SCHOOL;Algonquin, IL

Graduate

MILITARY:

11/1977 to UNITED STATES MARINE

CORP RESERVE

11/1993 Honorably discharged

Download Resume Format

About Author of the Website:

Neetu Singh is the founder of Resume Formats .Neetu Singh holds an Engineering degree in Computer Science with MBA Degree in Finance and Human Resource (HR). Currently she is running a Global Manpower Consultancy. Contact Her Here

Resumes By Categories

1-5 Years Experienced CV

10-15 Years Experienced CV

10th Standard

12th Standard CV

15-20 Years Experienced CV

20-25 Years Experienced CV

30+ Years Experienced CV

5-10 Years Experienced CV

Accounts CV

Aeronautical CV

Automobile Engineer

B Com CV

B Pharma CV

B.Tech CV

BA CV

BA Philosophy CV

Banking CV

BBA CV

BBM CV

BCA CV

BDS CV

Beautiful CV

Bio Technology CV

BMS CV

BPO Call Center CV

BSC CV

BSC IT CV

Business Analyst CV

CA CV

Cashier CV

CEO CV

CFA CV

Chemical CV

Civil Engineering CV

CMA CV

Commercial CV

Cook CV

Cover Letter for Resume

CS CV

D Pharma CV

Diploma CV

Doctor CV

draff

Economist CV

Electrical CV

Electronics CV

Engineer CV

Fashion Designer CV

Films CV

Finance CV

Foreign Resume Format

Fresher CV

GM CV

Hotel Management

Housekeeping CV

HR CV

ICWAI CV

Import Export CV

Industrial Engineering CV

Instrumentation CV

Insurance CV

IT CV

ITI CV

journalist CV

LLB CV

M Com CV

M Pharma CV

M Phil CV

M Sc Computer Science CV

M Tech CV

M.Tech

MA CV

Manager CV

Marketing CV

Mass Communication CV

MBA CV

MBA Event Management

MBA Finance

MBA Hospitality CV

MBA HR CV

MBA IB cv

MBA Marketing

MBA Production

MBA Quality

MBA SCM CV

MBA System

MBBS CV

MCA CV

MD CV

Mechanical CV

Medical Representative CV

Mining CV

MMS CV

MS CV

MSC CV

NETWEAVER CV

Over 25 Years Experienced CV

Paint Technology CV

Pharmacy CV

Phd CV

Philosophy CV

Project Manager CV

Psychology CV

Purchase CV

Quality Engineer

Real Estate CV

SAP ABAP CV

SAP Basis

SAP BI CV

SAP BO CV

SAP CRM CV

SAP CV

SAP FICO CV

SAP HR CV

SAP MM CV

SAP PP CV

SAP SD CV

SAP Security

Six Sigma CV

Special Resume

System Administrator CV

Teacher CV

Textile CV

Treasury CV

USA Resume

Web Designer CV

.JPG)

0 comments:

Post a Comment