Download Resume Format

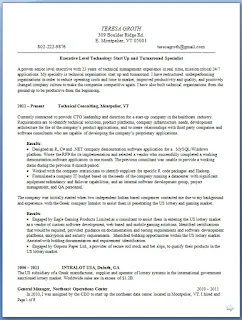

Technical Consultant Resume Format in Word Free Download

Sample Template Example of Beautiful Excellent Professional Curriculum Vitae / Resume / CV Format with Career Objective, Job Description, Skills & Work Experience for Freshers & Experienced in Word / Doc / Pdf Free Download

Download Resume Format

Executive Level Technology

Start Up and Turnaround Specialist

A

proven senior level executive with 23 years of technical management experience

in real time, mission critical 24/7 applications. My specialty is technical

organization start up and turnaround. I have restructured underperforming

organizations in order to reduce operating costs and time to market, improved

productivity and quality, and positively changed company culture to make the

companies competitive again. I have also built technical organizations from the

ground up to be productive from the beginning.

2011 –

Present

Technical Consulting, Montpelier ,

VT

Currently

contracted to provide CTO leadership and direction for a start-up company in

the healthcare industry.

Requirements

are to identify technical solutions, product platforms, company infrastructure

needs, development architecture for the of the company’s product applications,

and to create relationships with third party companies and software consultants

who are capable of developing the company’s proprietary applications.

Results:

· Designed

an R, C# and .NET company demonstration software application for a MySQL/Windows platform. Wrote the RFP for

its implementation and selected a vendor who successfully completed a working

demonstration software application in one month. The previous consultant was

unable to provide a working demo during the previous 6 month period.

· Worked

with the company statisticians to identify suppliers for specific R code

packages and Hadoop.

· Formulated

a company IT budget based on the needs of the company running a datacenter with

significant equipment redundancy and failover capabilities, and an internal

software development group, project management, and QA personnel.

The

company was initially started when two independent Indian based companies

contacted me due to my background and experience with the Greek company

Intralot to assist them in penetrating the US

Results:

· Engaged

by Eagle Gaming Products Limited as a consultant to assist them in entering the

US lottery market as a vendor of custom software development, web based and

mobile gaming solutions. Identified certifications that would be required,

provided guidance on documentation and testing requirements and software

development platforms, encryption and security requirements. Identified

bidding opportunities within the US

· Engaged

by Gopson Paper Ltd., a provider of secure roll stock and bet slips, to qualify

their products in the US

2006 –

2011 INTRALOT USA, Duluth,

GA

The US

General

Manager, Northeast Operations Center 2010 – 2011

In 2010, I was assigned by the CEO to start up the

northeast data center located in Montpelier, VT. I hired and managed a staff of

35 individuals. Responsibilities included management of the Northeast

data center, call center and local IT personnel. Also managed the Vermont field

service and marketing departments. Hands on involvement with Vermont and New

Hampshire state lottery project planning which included requirement definition,

specification, design and roll out of both systems.

Results:

· Brought

the system into production ahead of schedule by 4 days in order coincide the

system switchover with start of the VT lottery accounting week. This eliminated

the need to perform time consuming and resource intensive reconciliation and

conversion efforts.

· Brought

the project into production under budget by $340K or 9% of budget.

· Hired

and trained the staff of 35 people in a short 4 month time frame.

· Oversaw

the successful third party DSL communication network installation in VT and NH

under a tight time schedule.

· Operation Start Up

On

April 23, 2010, two months before the production go live date; there was a fire

at the data center building. There was significant damage to the structure. It

was necessary to find a temporary facility and resume the pre-go live

activities at that temporary location. Identified and leased a satisfactory building

and moved operations and the warehouse in just three days time. Worked with the

landlord of the burnt building to expedite repairs and the building was ready

for occupancy on June 15. Started

production operation on June 27 which was 4 days prior to the contract date in

spite of this potentially devastating setback.

Chief

Information Officer / Vice President, Systems 2006 – 2010

Recruited by and reported to the CEO of the US Intralot

subsidiary to create and lead an IT department within the US to service the US

market. Responsible for software development, quality assurance, project

management, and all IT system and administration functions for the US

operation. Created the organization structure to address these responsibilities,

hired the staff and managed the operation.

The creation of the US organization was critical to

success. The US market perceived a lack of available local support from the

Greek parent company, and thus were wary of awarding contacts to Intralot. Without

overcoming this perception, future US contracts were at risk. Prior to this

effort, the

company had been awarded three state lottery contracts over a four year period from

2002 to 2006.

Results:

· From

2006 to 2010 eight new state customer contracts were awarded to Intralot out of

11 that went to bid.

· Reduced

open system trouble reports at go live from over 250 to less than 60 per

customer.

· Reduced

on site travel requirements from over 8 weeks per engineer to 4 weeks without

requiring additional engineers to travel.

· Hired

and managed the US software staff to develop back office applications for

instant tickets including ad hoc reporting, order prediction, order processing

and management dashboards using .NET, C#, C and Crystal reports.

· Directed

the development of a data warehouse and data mining application as a product

differentiating offering for the company. Implemented the application using SQL

rather than Oracle to reduce costs, speed development and make the software

easier to maintain.

· Software

development using AIX, IBM hardware, Oracle and SQL database, C, C++, C#,

Windows and Crystal Reports.

· The

IT group was responsible for all US communications and systems. Systems were

duplexed 100% with no single point of failure.

· Software

development start up costs were identified correctly which enabled the company

to correctly estimate these costs for project budgets. Prior to formation of

the organization, costs were not accurately estimated or controlled.

· Negotiated VSAT communications vendor

contracts to reduce costs by $37 per month per drop. This impacted slightly

less than 11,000 drops.

· Never

missed a system startup date or a feature upgrade date for any customer.

· Contract Awards

After

taking the position, I devised an organization and staffed it with the key

individuals who could present a local face for the company, and respond quickly

to issues. Implemented a structured design process to better budget and plan

timelines and resources during a growth period where resources were being

stretched to the limit. Implemented IT security standards and lottery industry

best practices here in the US in order to meet contract prerequisites necessary

for Intralot to qualify to bid on state lottery projects. Created a testing

infrastructure to allow QA to test systems without using production systems as

had been the case. Created a marketing demonstration system so that we could

demonstrate system performance characteristics in response to customer requests

for proposals. Provided technical sales support and input to all project

proposals. I also instituted simple control processes to better capture and

track requirements. Visited lottery sites and met with the management to

identify areas of concern and demonstrate to them through process records that

the concerns were being met. The company gained a better reputation for being

customer-centric during this time, and this allowed us to win the majority of

new bids during the coming 4 years, including the 6th largest state

lottery – Ohio.

· Trouble Report Reduction

Established

a formal method using off the shelf software to track customer problems and

requests and to communicate these concisely to the developers. Using this

process allowed the company to identify exactly what the problem and solution

was, to track the severity and priority, and to communicate internally and

externally about the status. Prior fault and enhancement records were not

centralized or standardized and thus were lost or misinterpreted. Because this

formal problem tracking method was initiated, problems were addressed quickly

and efficiently and then prioritized into software releases depending on their

severity and the customer’s timing requirements. This reduced costs and greatly

increased efficiency. The number of open problems were reduced and the customer

satisfaction rating increased.

· VSAT contract negotiations

In

2006 there was only one VSAT vendor who was willing to do business with the

company due to the small amount of business the company was doing – about 2,000

VSAT installed drops at the time. Negotiated a substantially better arrangement

with a larger VSAT provider based on the forecast of increased future installations.

Negotiating this contract also provided the company additional capabilities

including the use of primary and secondary hubs and multiple satellites. This

made our bids more compelling to customers and became a product differentiating

feature in our bids.

1994 –

2006 INTERNATIONAL LOTTERY

& TOTALIZATOR SYSTEMS, Carlsbad, CA

A manufacturer

and provider of on-line lottery and horse racing products to the international

market with annual sales in excess of $20M.

Chief

Technical Officer / Vice President, Technical Operations

Hired by and reported to the CEO to turn around the

technical operation.

Upon arrival, found top heavy organization whose culture

was to design and build custom products totally in house. The company was

losing more and more market share due to high cost and long lead times. The technical department operating expenses were

extremely high, and the existing business model was not sustainable. My charter

was to evaluate all areas and make changes that would make the company more

competitive. The technical operations department consisted of

electrical, mechanical, and software engineering, project management, technical

publications and training, purchasing and material control, manufacturing,

customer service, and quality assurance. Performed work flow analysis, staff

evaluation and rightsizing. Implemented both structured design and project

management processes to make the new organization function with reduced project

overhead, improve quality, and lower, controlled costs. Worked with vendors to

reduce costs and improve supply chain efficiency. Specified and selected a

Taiwan POS manufacturing partner, and an Indian off shore software development

center to reduce overhead, improve cash flow, and increase scalability.

Results:

·

Restructured all departments upon

arrival to focus the company on customer requirements and elimination of

non-value added activities which resulted in annual savings of $1.3M and

headcount reduction of 25 individuals.

·

Led R&D to redesign the basic POS terminal

product to reduce cost from over $5,000 per terminal to $1,117 while

maintaining product quality and adding features.

·

Redirected the design philosophy to use

industry standard, off-the-shelf architecture to reduce time to market from an

average of 14 months to 6 months.

·

Reduced on hand inventory from $12M to

$1.2M in first two years.

·

Led the company effort to attain ISO

9001 certification – the first lottery company to do so.

·

Lowered the software development person

month (MM) cost from $97,000 to $46,000 by blending in off-shore development

company, while maintaining the quality of the software through tight oversight

of the work. Ported software development to C, C++, and Java. Implemented Linux

OS in all terminal products.

·

Organization

Restructure

Analyzed

the work flow of all departments to determine where areas of inefficiency and

waste existed. For example, I found a 10 person drafting organization that was

generating unnecessary documentation in order to keep the staff busy (creating drawings

for nonexistent product configuration options). Also found a hardware

development staff that had three levels of management and several technology specialists

when a generalist could easily perform the work. After completing the analysis,

the departments were right sized and in some cases consolidated or merged to

best meet or requirements (the hardware development department was moved under

the manufacturing department to eliminate dysfunctional silos of activity).

·

Product

Development Model

The

company development model was to create all products in house using custom

mechanical and electrical design and writing low level software drivers to

manipulate the equipment. This method resulted in excellent quality and

robustness, but the worldwide customer base desired lower costs and quicker

delivery over extraordinary quality. Initiated the philosophy of using third

party, industry standard, off the shelf components to solve customer

requirements. This reduced development and maintenance costs. The availability

of software design tools and standard software operating systems available with

the standard components greatly simplified software application development and

allowed for the development of high quality reusable software modules. As a

final step, a MMI level 5 offshore software development center was hired to

perform module development which resulted in high quality, low cost code.

·

Inventory

Reduction

Because

of the long lead time required to provide product at the company, previous

management kept enough raw material on hand to build 2,500 terminals in the

event that a contract was awarded. Their intent was to top off this inventory

as product was sold so there was always a buffer of material to build 2,500

terminals. This amounted to $12M. As material sat on the shelf it became

obsolete in some cases, and at a minimum the warranty expired. Changed the

practice to sell off what we could through some new sales and through spare

parts inventory campaigns with existing customers and was able to eliminate

this exposure. The new design philosophy cut lead times by a factor of ten

without negative impact to customer delivery expectations.

1992

– 1994 PM-DATA, Laguna

Hills, CA

A

start-up company providing automated data acquisition products and systems for

industrial applications.

Vice

President, Product Development

Offered

the position for a stock ownership package and reported to the president.

Responsible for the product conception, development and deployment of client

server systems consisting of hand held computer clients, bar code

identification software, narrow band and spread spectrum radio communications and

a small staff of software developers. Performed technical marketing, sales and

project management role for the company.

Results:

·

Designed and built a private network

radio communication system to mange maintenance work orders and EPA compliance

work orders using hand held, POS terminals. Installed, tested and trained

operators on the use of the system which was sold to Scott Paper company in Mobile , AL and Westbrook , ME.

1989

– 1992 SCIENTIFIC ATLANTA,

San Diego, CA

A $50M division

of Scientific Atlanta that designed and manufactured commercial and military

signal processing instrumentation and systems including spectrum analyzers,

passive SONAR systems, and vibration measurement and control equipment.

Engineering Manager

Hired

by the division president to lead the consolidation of four separate division

engineering groups into one functional team. and to foster a uniform company

culture. The organization consisted of 122 engineers and support technicians

responsible for systems, hardware, software, mechanical, reliability, and

components engineering as well as logistics support. Directed software

development to comply with MIL-STD-2167A.

Results:

· Engineering

department consolidation resulted in annual savings of $2.2M.

· Managed

the design of the first ever portable helicopter rotor balancing system.

Delivered to US Army for use on Black Hawk helicopter rotors.

· Managed

the design of a suite of five radically new acoustic and vibration monitoring

instruments including a windows based spectrum analyzer.

· Managed

the design of the passive SONAR system used on the Seawolf Class of US Navy

submarines.

1986

– 1989 PALOMAR TECHNOLOGY INTERNATIONAL,

Carlsbad, CA

A

producer of vibration monitoring instrumentation for machinery predictive

maintenance that was acquired by Scientific Atlanta in 1989.

Hardware Development Manager/Senior

Project Engineer

Hands-on

management and technical role in the design of hardware, firmware and

mechanical packaging of portable, battery powered data acquisition and signal

processing instrumentation. Reported to the VP of Engineering.

1979 –

1986 BENTLY NEVADA CORPORATION,

Minden, NV

Global market leader

in the design and manufacture of vibration monitoring and control equipment acquired

by General Electric in 2004.

North

American Product Service Manager 1982 - 1986

Promoted

to this position by the director of Worldwide Service. Managed a service force

of 55 people in thirteen area offices throughout North

America . Created formal training programs, a turnkey systems

installation services and a software services group. Grew the business from

$1.7M to $3.8M in one year.

Senior

Designer 1979 - 1982

Hired

by the department manager to designed instrumentation controllers, DMA

interfaces, communication links, and a proprietary communication protocol.

1972 –

1979 HUGHES AIRCRAFT CO.,

Fullerton, CA

A DOD

manufacturer of ground based RADAR, control and communication equipment.

System

Design Engineer - MTS

Hired

by the department manager to design disk controller systems for submarine fire

control systems, satellite ground terminals, and air traffic control consoles. Performed

system installation and customer training in Europe and Far

East on SATCOM satellite ground terminals.

EDUCATION:

BSEE, U.C. Santa Barbara, CA 1972

Download Resume Format

About Author of the Website:

Neetu Singh is the founder of Resume Formats .Neetu Singh holds an Engineering degree in Computer Science with MBA Degree in Finance and Human Resource (HR). Currently she is running a Global Manpower Consultancy. Contact Her Here

Resumes By Categories

1-5 Years Experienced CV

10-15 Years Experienced CV

10th Standard

12th Standard CV

15-20 Years Experienced CV

20-25 Years Experienced CV

30+ Years Experienced CV

5-10 Years Experienced CV

Accounts CV

Aeronautical CV

Automobile Engineer

B Com CV

B Pharma CV

B.Tech CV

BA CV

BA Philosophy CV

Banking CV

BBA CV

BBM CV

BCA CV

BDS CV

Beautiful CV

Bio Technology CV

BMS CV

BPO Call Center CV

BSC CV

BSC IT CV

Business Analyst CV

CA CV

Cashier CV

CEO CV

CFA CV

Chemical CV

Civil Engineering CV

CMA CV

Commercial CV

Cook CV

Cover Letter for Resume

CS CV

D Pharma CV

Diploma CV

Doctor CV

draff

Economist CV

Electrical CV

Electronics CV

Engineer CV

Fashion Designer CV

Films CV

Finance CV

Foreign Resume Format

Fresher CV

GM CV

Hotel Management

Housekeeping CV

HR CV

ICWAI CV

Import Export CV

Industrial Engineering CV

Instrumentation CV

Insurance CV

IT CV

ITI CV

journalist CV

LLB CV

M Com CV

M Pharma CV

M Phil CV

M Sc Computer Science CV

M Tech CV

M.Tech

MA CV

Manager CV

Marketing CV

Mass Communication CV

MBA CV

MBA Event Management

MBA Finance

MBA Hospitality CV

MBA HR CV

MBA IB cv

MBA Marketing

MBA Production

MBA Quality

MBA SCM CV

MBA System

MBBS CV

MCA CV

MD CV

Mechanical CV

Medical Representative CV

Mining CV

MMS CV

MS CV

MSC CV

NETWEAVER CV

Over 25 Years Experienced CV

Paint Technology CV

Pharmacy CV

Phd CV

Philosophy CV

Project Manager CV

Psychology CV

Purchase CV

Quality Engineer

Real Estate CV

SAP ABAP CV

SAP Basis

SAP BI CV

SAP BO CV

SAP CRM CV

SAP CV

SAP FICO CV

SAP HR CV

SAP MM CV

SAP PP CV

SAP SD CV

SAP Security

Six Sigma CV

Special Resume

System Administrator CV

Teacher CV

Textile CV

Treasury CV

USA Resume

Web Designer CV

.JPG)

.JPG)

0 comments:

Post a Comment